Printing Workshops

The Printing Press

Photographs of the Exhibition

The Press before refurbishment

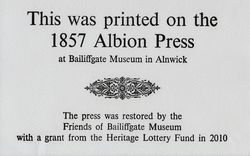

After refurbishment

Printing Workshops

Alnwick's Printing History

Printing Equipment

Publicity

Favorite Links

Printing Workshops

We were able to use the talents of many local people who had worked in the local printing industry, as well as experts from outside the area.

In addition, we were able to call upon the talents of a local commercial printer plus two Community Educational professionals.

Here are just a few of the photos taken from such public workshops.